Inventory doesn't have to be complicated. You just need a clear system for what stays, what sells, and what gets scrapped.

The problem is that over time, even good teams lose visibility on what’s sitting idle, what’s duplicative, and what’s in demand.

That’s why we recommend this 5-part surplus audit. It’s straightforward, fast, and designed to uncover exactly where your cash is tied up and where it could be freed.

You won’t need expensive software, although that can help. You won’t need 180-day approval chains. You just need an hour and a willingness to review your inventory with intention.

1. Traceability First: Know What’s Market-Ready

The first step in any effective audit is confirming which parts have full documentation.

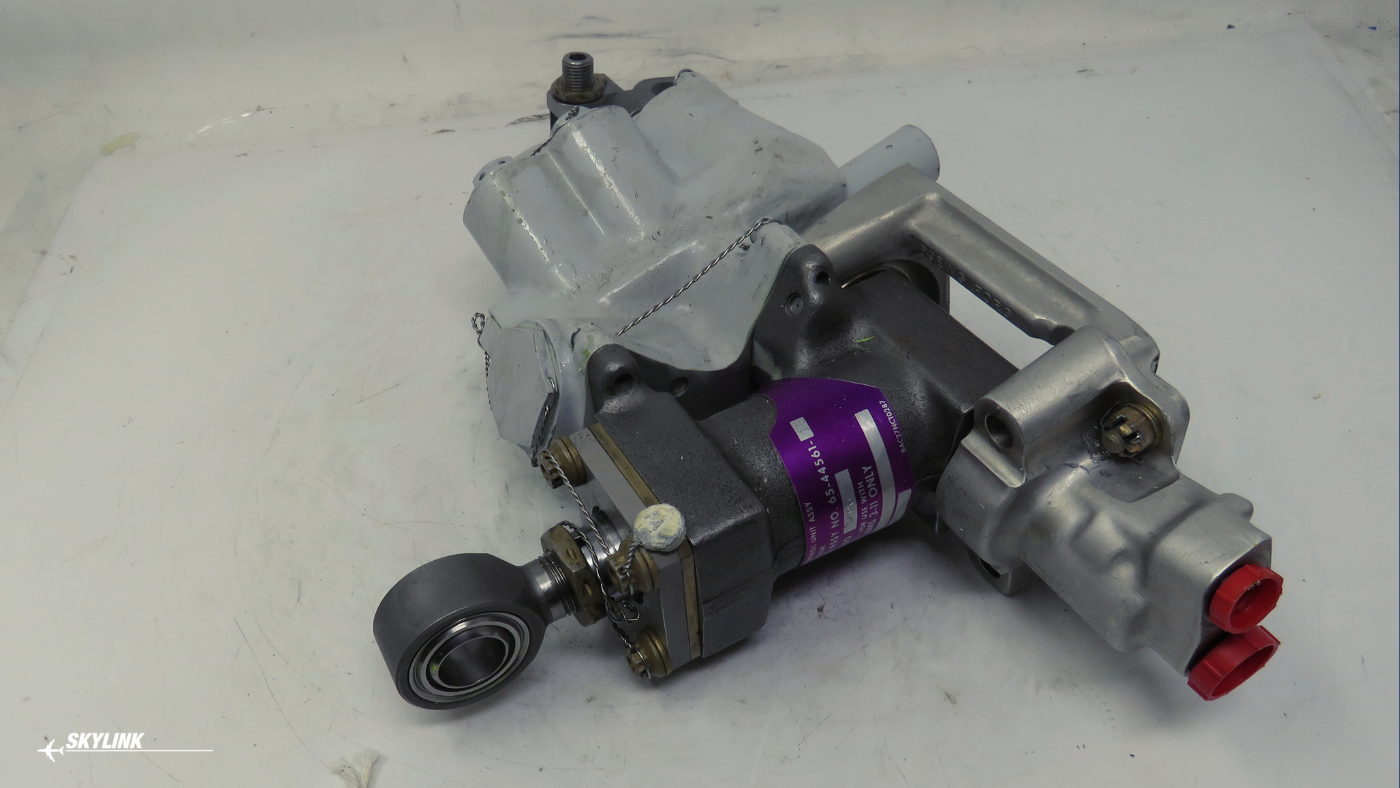

If a part has an 8130, an EASA Form 1, a teardown report, or a valid repair tag, it’s instantly more valuable on the resale market.

As you review your inventory, take note of what’s clearly documented and ready for resale.

These are your quickest paths to monetization.

Set aside anything with missing paperwork, not to discard, but to validate or resolve later. Focusing your time on market-ready, traceable, and certified parts prevents wasted quoting and gives your sales or procurement team clean targets.

2. Current Demand: Focus on What Fleets Actually Need

It’s easy to assume certain parts are valuable because of what they cost—or how hard they were to source. But value is dynamic.

A part only sells if someone needs it now.

Take time to cross-check your inventory against known removal trends, high-need components, or active AOG data.

Marketplaces like ILS and PartsBase can help surface which PN categories are seeing the most movement.

When you find overlap between what you have and what’s in demand, that’s your signal to prioritize those listings.

It’s not just about what’s on the shelf, it’s about what’s in motion.

3. Redundancy Review: Multiples Without Movement

Redundancy isn’t always bad, especially when parts support a contracted fleet or a high-need part number.

But if you’re holding three or more of the same part number and none have moved in the past 12 months, that’s worth revisiting.

Start by asking whether those units are reserved or planned for future use. If not, they’re likely excess.

That’s inventory costing you space, attention, and carrying cost.

The goal isn’t to purge—it’s to prioritize.

Flag excess units for liquidation or bundle pricing to convert passive inventory into active capital.

4. Age Matters: Time on the Shelf Tells a Story

When a part sits for years without a single use, its resale window narrows.

Use procurement dates, last-used entries, or repair dates to surface what’s gone cold. Once you spot aging inventory, bring it to the front of your disposition strategy.

These units are the best candidates for bundled sales, discounts, or last-chance listings.

A traceable part that’s three years old is still better than one with no paperwork, but it won’t get more valuable the longer it waits.

Treat aged stock like expiring food; move it while it’s still good.

5. Market Saturation: Know When You’re Holding a Commodity

The final step is understanding how common your inventory really is.

When a part number appears on hundreds of global listings, your leverage is limited. Buyers know they have options, and they’re shopping on price or lead time.

Run basic scans across major platforms to see how many others are holding the same item.

If the number’s high, it’s time to get aggressive: sharpen the price, offer a bundle, or combine it with harder-to-find parts to increase appeal.

Value is driven by scarcity, and when you’re holding a commodity, speed becomes your best strategy.

An aircraft part surplus audit doesn’t have to be a significant project.

It’s a practical way to make sure your shelves work for you, not just for storing history.

By focusing on traceability, demand, redundancy, age, and saturation, you’ll quickly surface what’s ready to move and what needs a plan.

Skylink helps operators do this every day, quietly, quickly, and with zero disruption.

If you want a second set of eyes or need help turning surplus into working capital, reach out.

We’ll guide you through a rapid, ROI-driven review built for teams who don’t have time to waste.